Technological innovation at the service of our wines

nfc capsules

Premiers crus & grand crus connected

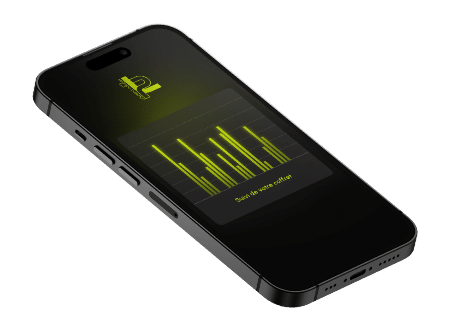

Thanks to an app on your smartphone, it's now possible to check whether the bottle you're holding in your hands actually comes from our house.

These tamper-proof chips are integrated into our capsules and feature two extensions that also stop the data if the bottle is opened.

Simply place the smartphone over the capsule and the reading is instantaneous.

Monitoring 2.0

Smart box

Our Premiers Crus and Grands Crus cases are equipped with a sensor that records the temperature every three hours and keeps an up-to-date history.

They are therefore able to calculate the impact of temperature conditions on wine quality and provide a score interpreting any deterioration.

These intelligent crates ensure that your wines are transported and stored in the best possible conditions, before you store them in your cellar.

the ideal cap

Technological shutters

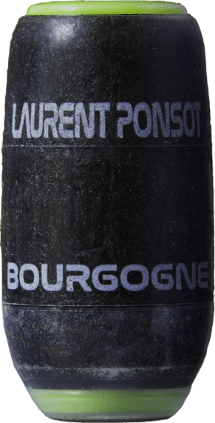

This corking concept, consisting of an internal frame and a shield, both combined with a thermoplastic elastomer, is known as a technological obturator, and scientifically controls the amount of oxygen the wine receives over a given period.

- Lets wine breathe

- Prevents leakage

- No cork taste

- Bottles can be left upright

- Fully recyclable

temperature control

Thermal idicato

Laurent Ponsot sought to give consumers an indication of a possible temperature problem.